In the ever-evolving landscape of industrial and manufacturing processes, one technology stands out for its efficiency, speed, and precision – UV curing systems. These systems have become indispensable in various industries, revolutionizing the way we achieve rapid and flawless results. In this blog, we’ll embark on a journey to explore the fascinating world of UV curing, unraveling the technology behind it and delving into its diverse applications.

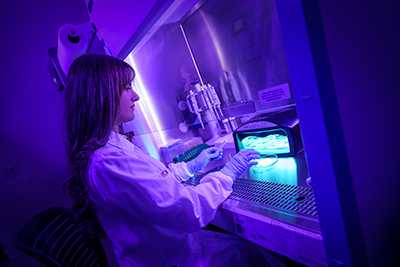

Understanding UV Curing: UV curing is a process that utilizes ultraviolet (UV) light to instantly cure or dry inks, coatings, adhesives, and other materials. UV curing systems consist of a UV light source, a reflector, and a cooling system. The key to their effectiveness lies in the ability of UV light to trigger photochemical reactions, leading to the rapid polymerization of coatings or inks, resulting in a hardened, durable finish.

Unparalleled Speed and Precision: One of the standout features of UV curing systems is their incredible speed. Traditional curing methods often involve lengthy drying times, leading to production bottlenecks. UV curing, on the other hand, offers near-instantaneous curing, significantly reducing processing times. This not only enhances overall productivity but also allows for streamlined workflows and faster time-to-market.

Moreover, UV curing systems boast exceptional precision. The controlled and targeted application of UV light ensures uniform curing across surfaces, eliminating the risk of uneven coatings or incomplete curing. This precision is particularly crucial in industries such as electronics, automotive, and printing, where high-quality finishes are non-negotiable.

Applications Across Industries: UV curing systems have found applications in a diverse range of industries, transforming the way products are manufactured. In the printing industry, UV curing has become synonymous with vibrant and durable prints on various substrates. In electronics manufacturing, UV curing ensures the reliability of coatings on sensitive components. The automotive sector benefits from the rapid curing of coatings, contributing to the efficiency of production lines.

Innovations Driving Progress: Recent advancements in UV curing technology continue to push the boundaries of what is possible. LED-based UV curing systems, for instance, offer energy efficiency and a longer lifespan compared to traditional mercury vapor lamps. These innovations not only reduce environmental impact but also contribute to cost savings for businesses adopting UV curing technology.