In today’s fiercely competitive business landscape, maintaining quality standards is paramount. Customers expect nothing less than excellence, and organizations that can consistently deliver top-notch products and services often emerge as industry leaders. One methodology that has stood the test of time and proven its worth in quality management is six sigma. In this blog, we’ll take a comprehensive look at Six Sigma, exploring its origins, principles, methodologies, benefits, and real-world applications.

Origin of Six Sigma

Six Sigma was originally developed by Motorola in the 1980s and later popularized by companies like General Electric under the leadership of Jack Welch. The term “Six Sigma” refers to a statistical measure of process performance, specifically indicating that a process is operating with minimal defects. In essence, Six Sigma aims to achieve near-perfect quality by minimizing variability in processes and products.

Principles of Six Sigma

Six Sigma is built on a set of core principles:

- Customer Focus: Understanding and meeting customer requirements is the primary goal of Six Sigma.

- Data-Driven: Data and statistical analysis drive decision-making, ensuring that changes are made based on evidence rather than intuition.

- Process Orientation: Six Sigma views every aspect of a business as a process, and improving these processes is key to achieving quality.

- Continuous Improvement: The pursuit of perfection is ongoing, with a focus on incremental improvements.

- Teamwork: Cross-functional teams collaborate to identify and solve problems.

- Leadership Engagement: Leadership plays a crucial role in championing Six Sigma initiatives.

Methodologies of Six Sigma

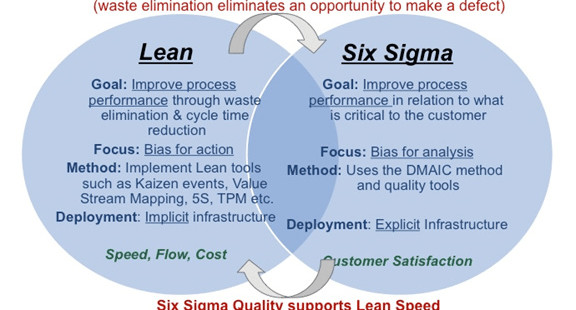

There are two primary methodologies within Six Sigma: DMAIC and DMADV.

- DMAIC (Define, Measure, Analyze, Improve, Control): This methodology is used for improving existing processes. It involves defining the problem, measuring process performance, analyzing data, making improvements, and implementing controls to sustain improvements.

- DMADV (Define, Measure, Analyze, Design, Verify): DMADV is used for designing new processes or products. It includes defining customer requirements, measuring process capabilities, analyzing data, designing the process or product, and verifying its performance.

Benefits of Six Sigma

Implementing Six Sigma can yield numerous benefits for organizations:

- Improved Quality: Reduced defects and errors lead to higher product and service quality.

- Cost Reduction: By optimizing processes and eliminating waste, Six Sigma can result in significant cost savings.

- Enhanced Customer Satisfaction: Meeting and exceeding customer expectations leads to increased customer loyalty.

- Increased Efficiency: Streamlined processes are more efficient, saving time and resources.

- Better Decision-Making: Data-driven decision-making improves overall business performance.

Real-World Applications of Six Sigma

Six Sigma is applicable across various industries and has been successfully implemented in areas such as:

- Manufacturing: Reducing defects in production processes.

- Healthcare: Enhancing patient care by minimizing errors and improving processes.

- Finance: Optimizing financial processes to reduce errors and improve efficiency.

- IT: Improving software development and project management processes.

- Retail: Enhancing supply chain and inventory management.

- Aerospace: Ensuring the safety and reliability of aerospace components.