In the world of materials science and engineering, innovation knows no bounds. One such remarkable innovation that has been making waves in various industries is Copper Coated Film. This thin, versatile material is revolutionizing everything from electronics to solar power, and its applications are only growing. In this blog, we will dive deep into the world of Copper Coated Film, exploring its properties, uses, and the impact it’s having on different sectors.

The Science Behind Copper Coated Film

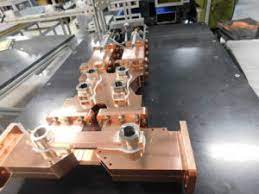

Copper Coated Film is a thin layer of copper deposited onto a flexible substrate, typically made of materials like polyethylene terephthalate (PET). The process involves vacuum deposition or electroplating, resulting in a uniform copper coating with exceptional adhesion properties. The thickness of the copper layer can vary depending on the intended application, ranging from a few micrometers to a few millimeters.

Key Properties of Copper Coated Film

- Conductivity: One of the most significant advantages of copper-coated film is its exceptional electrical conductivity. Copper is known for its high conductivity, making it an ideal choice for applications in the electronics and telecommunications industries.

- Flexibility: The thin, flexible substrate allows the copper-coated film to conform to various shapes and sizes, making it adaptable for use in flexible electronics, wearable devices, and even curved surfaces.

- Durability: Copper-coated film is highly resistant to corrosion, ensuring long-term performance in harsh environments. This property is invaluable in applications such as outdoor signage and solar panels.

- Heat Resistance: Copper has excellent thermal conductivity, which makes copper-coated film suitable for applications that require efficient heat dissipation, such as LED lighting.

Applications of Copper Coated Film

- Electronics: Copper-coated film is a crucial component in the manufacturing of printed circuit boards (PCBs). Its high conductivity and flexibility allow for intricate circuit designs and miniaturization of electronic devices.

- Solar Power: In the renewable energy sector, copper-coated film is used in the production of thin-film solar cells. Its ability to absorb and conduct electricity efficiently makes it an essential component for converting sunlight into electricity.

- Antennas and RFID Tags: The film’s conductive properties make it ideal for manufacturing antennas and radio-frequency identification (RFID) tags, which are used in various industries for communication and tracking purposes.

- Decorative Applications: Copper-coated film can be employed for decorative purposes, such as architectural finishes and interior design elements, where its metallic sheen adds a touch of elegance.

- Circuit Protection: It is used for electromagnetic interference (EMI) shielding and grounding in electronic devices, safeguarding sensitive components from external interference.

The Future of Copper Coated Film

As technology continues to advance, the demand for materials that can deliver high performance, flexibility, and sustainability is on the rise. Copper-coated film is well-positioned to meet these demands and play a pivotal role in shaping the future of multiple industries. Ongoing research and development efforts are likely to lead to even more innovative applications for this remarkable material.

Conclusion

Copper-coated film represents a remarkable fusion of materials science and engineering, offering a wide range of applications across various industries. Its exceptional conductivity, flexibility, and durability make it a valuable asset in the development of cutting-edge technologies, from advanced electronics to clean energy solutions. As we continue to explore and harness the potential of copper-coated film, we can anticipate further breakthroughs that will drive innovation and transformation in our rapidly evolving world.