In the realm of technological innovation, materials science often takes center stage, pushing the boundaries of what we thought was possible. One such marvel that has been captivating industries across the board is the Copper Coated Film. This unassuming yet groundbreaking creation has revolutionized various fields, from electronics to solar power. In this blog, we embark on a journey of discovery, unraveling the mysteries and possibilities that Copper Coated Film brings to the table.

What is Copper Coated Film?

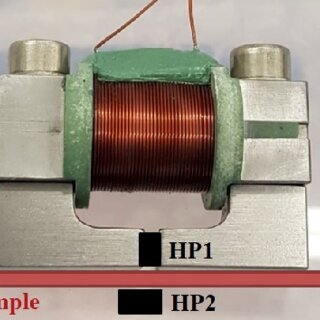

Copper Coated Film, as the name suggests, is a thin layer of copper applied to a flexible film substrate. This integration marries the flexibility and lightweight nature of films with the excellent electrical and thermal conductivity of copper. The result is a versatile material that opens the doors to a multitude of applications.

Applications that Shine:

- Electronics and Printed Circuit Boards (PCBs): The electronics industry has embraced Copper Coated Film for its remarkable conductivity and flexibility. It serves as an integral component in manufacturing flexible PCBs, enabling the creation of compact and lightweight electronic devices that can bend and conform to various shapes. From wearable tech to foldable smartphones, the possibilities are boundless.

- Solar Energy: The pursuit of clean and sustainable energy sources has led to the integration of Copper Coated Films in solar panels. The copper layer enhances the efficiency of energy transfer within the solar cells, contributing to improved overall energy conversion rates. This advancement brings us closer to a greener future.

- Antennas and RF Devices: The demand for high-performance wireless communication devices has driven the development of Copper Coated Film antennas. These antennas exhibit enhanced signal transmission and reception capabilities, making them a valuable asset in modern communication systems.

- EMI Shielding: In an increasingly interconnected world, electromagnetic interference (EMI) can be a significant concern. Copper Coated Films act as effective shields, preventing unwanted electromagnetic radiation from interfering with sensitive electronic components.

- Conductive Tapes and Adhesives: The flexibility and conductivity of Copper Coated Film find applications in the creation of conductive tapes and adhesives. These are used for bonding and connecting electronic components, providing both mechanical strength and electrical conductivity.

- Lighting Technology: From LED displays to flexible OLED lighting, Copper Coated Films contribute to the advancement of lighting technologies. Their flexibility allows for the creation of innovative lighting solutions that can be integrated into various surfaces and shapes.

The Advantages and Challenges:

Copper Coated Film offers a plethora of benefits, including:

- High Conductivity: Copper is renowned for its excellent electrical conductivity, which allows for efficient energy transfer within electronic devices.

- Flexibility: The inherent flexibility of the film substrate makes Copper Coated Films ideal for applications that require bending and conforming.

- Weight Reduction: The lightweight nature of films combined with the conductivity of copper results in lightweight yet high-performance materials.

- Versatility: The material’s adaptability lends itself to various industries, from electronics to energy.

However, challenges such as material degradation over time, manufacturing complexities, and cost considerations are still areas that researchers and engineers are working to address.

The Future Beckons:

As technology continues to evolve, so do the possibilities of Copper Coated Film. Researchers and innovators are actively exploring ways to enhance the material’s properties, mitigate its challenges, and discover novel applications. With advancements in nanotechnology and materials science, we might witness even more remarkable feats made possible by Copper Coated Film.

In conclusion, Copper Coated Film stands as a testament to human ingenuity and the power of combining seemingly disparate elements to create something extraordinary. Its impact spans industries, powering our electronic devices, lighting our paths, and driving us towards a sustainable future. As we continue to unravel its potential, the future shines brighter with every innovation born from this remarkable material.